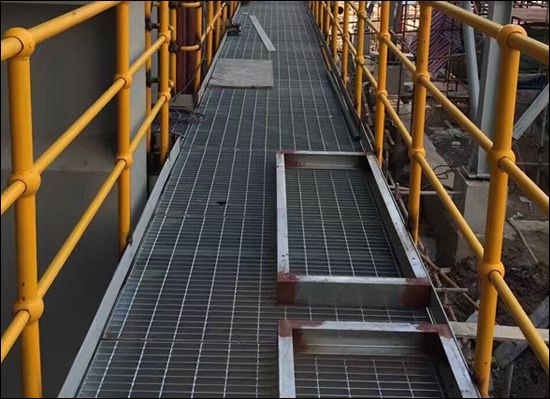

Smooth Surface Galvanized Steel I Bar Steel Grating for Walkways Platform Drain Cover

We specialize in high-quality guardrail systems including 358 Anti-Climb Mesh, Workshop Partitions, Elevator Guards, Highway, Airport, and Prison Fencing. Our products are manufactured from robust materials such as galvanized steel or powder-coated finishes, ensuring exceptional durability, corrosion resistance, and long service life.

Each solution is engineered for specific applications: 358 mesh offers superior security for prisons and airports, while anti-dazzle panels enhance highway safety. From securing critical infrastructure to organizing industrial workshops, we provide reliable protection and safety for demanding environments worldwide.

Features of Steel Grating

Steel Grating is welded bearing steel bars and cross twisted bars according to required pitch space between steel bars by steel grating welding machines. It is a grid building material.

All gratings are made using high quality standard steel materials which exhibit good hardness and high tensile strength. It is extremely strong, durable and corrosion resistant with great anti-slip performance.

Based on where the grating will be used and its load bearing requirements, steel bars are available in a range of spacing pitch, thicknesses and heights.

Surface Finishing of Steel Grating

Generally Steel Grating is made with hot-dipped galvanized. Also zinc coating can be made according to the client's requirement.

Steel Grating can be called hot-dip galvanized steel grating or stainless steel gratings. Beautiful surface appearance and excellent performance in industry construction projects.

Materials of Steel Bar Grating

- Low Carbon Steel Smooth Flat Bars, Low Carbon Steel Serrated Bars, Low Carbon I-Shaped Steel Bars

- Steel Twisted Square Cross Bars, Steel Round Cross Bars

- Stainless Steel 304 Grade Flat Bars, Stainless Steel 316 Grade Flat Bars

Steel Grating Specifications

| Series |

Pitch of Bearing bar |

Pitch of Cross bar |

Specifications of Bearing Bar (Width x Thickness) |

| 1 |

30 |

100 |

WA253/1 | WA253/1 | WA254/1 | WA404/1 | WA205/1 | WA255/1 |

| 50 |

WB253/1 | WB253/1 | WB254/1 | WB404/1 | WB205/1 | WB255/1 |

| 2 |

40 |

100 |

WA253/2 | WA323/2 | WA254/2 | WA404/2 | WA205/2 | WA255/2 |

| 50 |

WB253/2 | WB323/2 | WB254/2 | WB404/2 | WB205/2 | WB255/2 |

| 3 |

60 |

50 |

WB53/3 | WB323/3 | WB254/3 | WB404/3 | WB205/3 | WB255/3 |

| Series |

Pitch of Bearing Bar |

Pitch of Cross Bar |

Specifications of Bearing Bar (Width x Thickness) |

| 1 |

30 |

100 |

WA325/1 | WA405/1 | WA455/1 | WA505/1 | WA555/1 | WA605/1 |

| 50 |

WB325/1 | WB405/1 | WB455/1 | WB505/1 | WB555/1 | WB605/1 |

| 2 |

40 |

100 |

WA325/2 | WA405/2 | WA455/2 | WA505/2 | WA555/2 | WA605/2 |

| 50 |

WB325/2 | WB405/2 | WB455/2 | WB505/2 | WB555/2 | WB605/2 |

| 3 |

60 |

50 |

WB325/3 | WB405/3 | WB455/3 | WB505/3 | WB555/3 | WB605/ |

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!